Attention drones

Drones, for example, allow foremen and construction managers to quickly record construction progress. But there are also a number of hazards.

In the case of electrical hazards, an electric shock is conceivable during the charging process. Protection against direct or indirect contact with live parts is required here as a safety measure. In addition, regular testing of fixed and non-fixed charging devices, for example in emergency vehicles or the fire department depot, can help to minimize the risk of electric shock during a charging process. Short-circuiting due to reverse polarity of the battery or charging infrastructure must also be ruled out, for example by using connections that are protected against reverse polarity.

The mechanical hazard during drone operation can come from controlled moving but unprotected parts (e.g. propeller). Regular inspection for defects before each use is absolutely essential, as even a hairline crack in the propeller, for example, can spread over time to become a hazard due to propeller parts flying around. A propeller guard can be used to protect against contact. In addition, work procedures, especially before takeoff and after landing, must be designed to provide safeguards against accidental movement or contact. For example, the takeoff and landing area must be marked and secured against entry by unauthorized or uninvolved persons. This is not only relevant during the day, but also at night due to poor visibility conditions.

Sufficient lighting can increase visibility for third parties. Another mechanical hazard is the crash, tripping or falling over of the drone pilot, airspace observer or an assistant. Especially when launching from slopes or landing sites that are difficult to access, ensure surefootedness by wearing suitable footwear and remove obstacles or debris in the vicinity of the propellers. It can often be helpful to equip one of the emergency vehicles with a loading area (e.g. a pick-up truck) so that take-offs and landings can be carried out on the loading area. This saves time for set-up as well as lighting launch sites on open terrain and prevents the need to clear launch areas of obstacles such as small rocks that can be stirred up by air turbulence from the spinning propellers and damage the UAS. If the takeoff and landing site is set up on a vehicle, it is imperative that it is selected so that there are no large metal parts, e.g., on the loading area. Depending on the drone model, the magnetic field may be affected to such an extent that the drone's magnetic sensor indicates an error. In drone models with more than one magnetic sensor, i.e. those with redundant Integrated Measuring Unit (IMU), this effect is compensated for in most cases.

Unprotected moving drones in the air also pose a certain mechanical hazard, which can be reduced by impact protection. It is relevant to pay attention to the protection of the controlled area on the ground where the take-offs and landings take place and, in the case of heavier drones weighing 4 kg or more, also to the area under the drone in case of a crash. Since helmets are generally compulsory at the site of operation, the maximum impact energy of 89 joules calculated from civilian drone operation does not apply to drones up to 249 g.

Not only during normal operations, but also when recovering lost drones, there is a risk of the recovery personnel falling, for example if a mission drone has made an emergency landing on a steep slope in a tree. Here, too, surefootedness must be ensured by suitable footwear. Obstacles and debris must be removed accordingly.

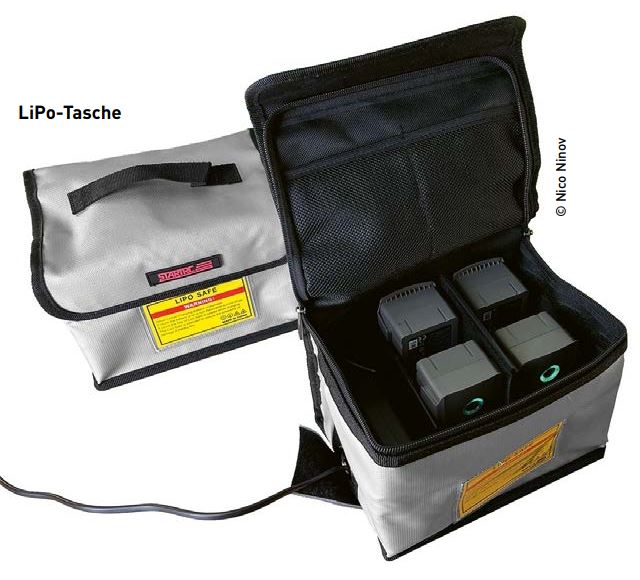

In the case of chemical hazards, the focus is on skin contact with solids and liquids or working with moisture. Skin protection (e.g. gloves) can be worn and a skin cleanser or care product used in the event of contamination. Outgassing of battery cells is also possible, which can be minimized by using lithium polymer batteries. Outgassing does not occur with these batteries. However, due to the extremely high energy density, the risk of ignition or explosion is conceivable, for example due to overheating, overcharging or mechanical overstressing of the battery. One countermeasure is the use of so-called LiPo bags, which should be used for storage, but also during a charging process. These can limit the spread of flames in the event of a fault by minimizing the supply of oxygen.

The exposure of the drone operations team to the work environment can have a negative impact on occupational safety, both physically and mentally. Physical stresses include lighting. Particularly at night, excessively illuminated take-off and landing areas or bright flashing lights on the drone can dazzle the pilots and other persons or impair their activities. Reflections from a flashing drone on the safety strips of the uniform can also be irritating. As a countermeasure, different illuminance levels should be used both at night and during the day, and the work areas should be selected in each case so that no danger can occur on the ground. If it is not otherwise possible, eye protection against glare can also be worn. Another physical impairment is the noise that can be generated by engines or propeller noise. This can be reduced by wearing hearing protection. Most operational helmets already have such hearing protection integrated.

The greatest mental stress from the work environment caused by the use of drones comes from long periods of concentration. Not only the drone pilots have to observe many parameters simultaneously during the flight in a highly concentrated manner, such as the battery status, sources of danger on the ground and in the air, radio messages from the airspace observers, position and orientation of the drone, but also the airspace observers can have difficulty concentrating after a while and should be relieved. This time value varies from person to person and must be determined individually for each airspace observer and drone pilot in the exercises. If this is not possible, the following guideline values must be observed:

- Drone pilot: 10 minutes break after 45 minutes flight

- Airspace observer: 15 minutes break after 90 minutes observation

Internal operating instructions can be drawn up for this purpose. Operational personnel should be instructed accordingly and safety instructions already available for work with long concentration phases should be applied as prescribed.