Hand in hand: safety and building technology?

The megatrend in security and building technology is formed by cross-trade sensors that allow devices to interact with their environment. Building on this, artificial intelligence and the Internet of Things create new cooperation models for companies and thus added value for customers.

Everyone is talking about digitalization and selling it as something new and revolutionary - yet building automation has only been digital for over 30 years. According to Brian Arthur (https://bit.ly/2WX3Dcv), an economist specializing in complex and high-tech economies, it is not digitization that is changing the world, but the ubiquitous sensors that record the environment and make the data available. Historically, the triumph of the digital began as early as the 1970s, when personal computers suddenly appeared alongside large, expensive and centralized computers, providing decentralized, inexpensive and small computing power thousands of times over. In the 1990s - strongly influenced by Tim Berners-Lee - the Internet was added, which now allowed data to be exchanged over large distances for everyone. From 2010, computers, which until then had been disconnected from the real world, increasingly began to make contact with the environment. The age of sensors is developing. Without sensors, self-driving cars and artificial intelligence are inconceivable. Both are dependent on exchange with the environment.

Megatrends artificial intelligence and IoT

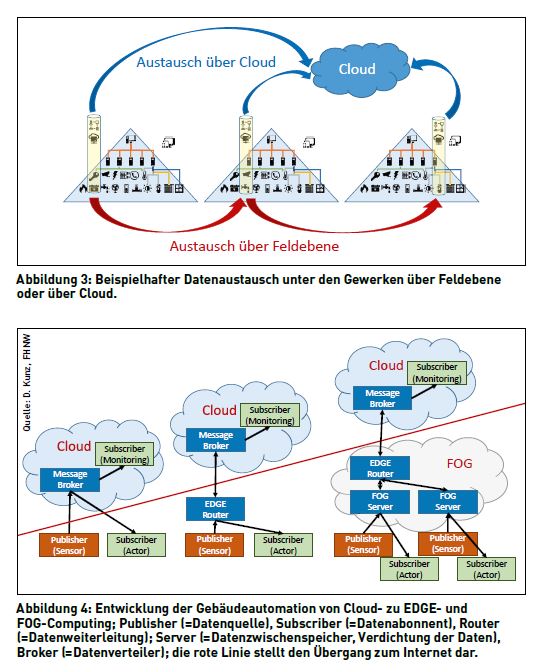

Up to now, there has been a human being behind every computer, and in buildings we have become accustomed to hierarchical structures with a strong division of labor: the field level measures and sets, the automation level regulates, and the management level controls and evaluates (EN 16484). According to Figure 1, thinking in terms of individual trades (heating, ventilation, lighting, fire protection, access, etc.) leads to silo-like structures, which are supplemented by communication to the Internet. This structuring is outdated, but is still used in practice. Today, decentralized devices interact without human intervention, making sensible decisions and learning from the past. Technology is approaching nature to some extent and hierarchical structures are being replaced by "organic" ones. This requires artificial intelligence (AI) and the Internet of Things (IoT).

Effects on the building and its operation

Buildings are planned, constructed, operated, and after a few decades, repurposed. The challenge that the technology used has a much shorter service life than the building structure must already be taken into account in the planning stage. For example, it must be ensured that over the life cycle of the building, the technology can be updated without any problems; this applies to hardware, software and communication.

In practice: Developing, planning and operating IoT solutions

When a building is being constructed, planners draw on existing and proven developments and try to create a new whole by cleverly combining partial solutions. In a rapidly changing world, they look for solutions that can be quickly adapted to new circumstances. IoT solutions must be characterized by special properties that affect both the hardware and software as well as the communication. Here are some important characteristics: The systems used must include versioning and build management. The security aspects have already been taken into account in the development phase, and it must be possible to keep the product up to date for years through updates and the introduction of new technologies. Whereas in the past, self-contained solutions were preferred, today it is important to rely on open standards. In addition, manufacturers who take minimum security standards into account should be given preference. Issues from the computer world such as confidentiality, data integrity and availability must be clarified in the planning phase.

The planning of building automation solutions is not limited to the technical aspects. It requires clarification of the roles (who is responsible for what?), the specifications for the buildings and their interaction. Already in this phase, the integral tests (leaflet SIA 2046), which guarantee functionality across all trades, are set up for the commissioning and operation of the buildings.

IoT solutions require new competencies on the part of employees as well as customers, manufacturers and authorities. In particular, it must be defined in advance how manufacturers can access the system, how future updates are made, how critical events are recorded, and how the necessary expertise of employees is retained. While previous systems were relatively secure from outside interference, this is a major challenge, especially for IoT systems. In addition to the requirements already mentioned, it is also necessary to plan how a previous software status can be reactivated in the event of a breakdown. A process description helps to systematically handle security incidents and clarify liability issues.

Data exchange: Today's structuring

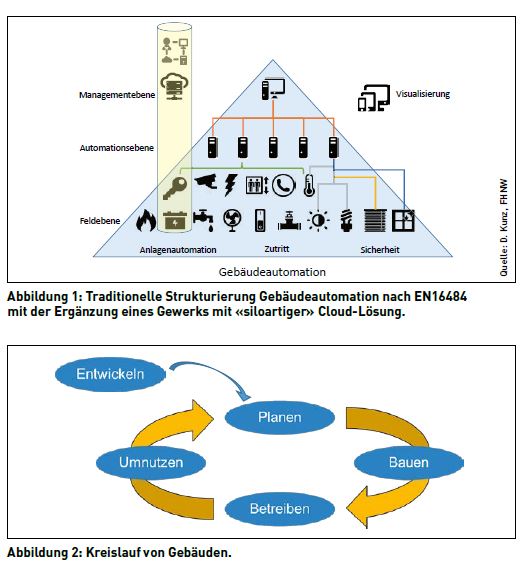

In practice, there are still many ways in which data can be exchanged. If the exchange takes place at the field level, one is fast and independent of upper levels. If everything is processed via the network in the cloud, you are universal, but slow and susceptible to communication failures (see Figure 3).

Data exchange: Future structuring

Today's customers expect their data, plant operating states and intervention options to be available worldwide and at any time. This demand favors Internet-based technologies with the corresponding connection of databases. In addition, hardware and software costs have fallen extremely sharply, and high computing power can be built directly into sensors in the smallest possible space. This technical development enables concepts that were previously unthinkable, but greatly increase the overall benefit of the system. In practice, a number of terms have become established that describe the technical characteristics of the solutions (see Figure 4):

Cloud computing: intelligence is outsourced to a "data center"; everyone communicates with the cloud via the Internet.

- EDGE computing: local intelligence is strengthened, there is ideally exactly one entry point for the Internet with the cloud connection; the firewall protection of the Internet is centralized, professionalized and can be maintained from one place.

- FOG computing: local intelligence is strengthened again; everything that can be decided locally remains local and does not make a detour over the Internet; an automation hierarchy is created locally, as in traditional building automation, the system becomes faster, more reliable and more stable; an EDGE router typically follows above the FOG servers.

FOG computing best solves today's problems. It allows

- locally distributed artificial intelligence, which can make its own decisions both networked and autonomously;

- Communication among smart devices without being prompted by a central authority;

- Learning from the past for the future and recognizing new devices without human intervention.

The central brain (management level) is no longer needed in today's function, as local artificial intelligence takes over this role. This increases reliability, and trades can exchange their data directly. Even the interruption of a communication line no longer leads to a standstill of the system.

The smart building: research and reality

The technology available today allows a building to be fully equipped and operated with the Internet of Things. This requires Ethernet-based cabling as the backbone, sensors that make their data available to all the others via their own trade, and algorithms that evaluate the sensor data for intelligent automation. No distinction is made between heating, cooling, lighting, access, fire protection or the location of people in the building. This brings us back to our initial thesis: the convergence of building and security technology is already a reality. It's not the technology that's holding us back, but old ways of thinking about the division into individual, independent trades. This must be overcome. While prototypes are only being built in Europe, progressive developers in California are already realizing the first small properties (example property at https://bit.ly/2HIIKv8).

The introduction of the Internet of Things is happening almost imperceptibly. In addition to the traditional trades, new fields will be added, such as the integration of "passive sensors", which can say something about the condition of components (e.g. sensors embedded in concrete, which can be read out according to the situation). This allows further networking in construction in the areas of planning, building, management and dismantling. This brings us to the topic of Building Information Modeling (BIM) with a digital twin.

Ultimately, it is not about creating a new technology without added value for the customer. This added value can be felt and experienced customer interactions (user experiences), customer-related services (personalized service), data analytics, and new business models and applications based on artificial intelligence. In other words, solutions will prevail that offer both added value for customers and earning opportunities for companies. Silo thinking will be overcome by collaborative solutions.

JÜRG BICHSEL

Prof. Dr. Dipl. El.-Ing. ETH, Head of Institute Energy in Construction, School of Architecture, Civil Engineering and Geomatics, University of Applied Sciences Northwestern Switzerland