Secure individual solutions

Fire protection in Switzerland is basically prescriptive. What is approved is what is certified. This prevents the use of innovative, new system solutions. Experimental verification of individual solutions would actually be permitted and could open up great potential for planners and builders. But current practice hardly makes use of them. It is time for new freedom.

The goal of fire protection measures is clear: they have to ensure that the specified protection goals are met with regard to people, animals and property. However, the best way to achieve this is by no means clear. Up to now, fire protection in Switzerland has basically been prescriptive, i.e., planning and approval are carried out according to the application guidelines specified in the fire protection regulations of the Association of Cantonal Fire Insurers (VKF). At the level of components and building products, this means that, as a rule, only certified products and systems are used. This approach is very efficient for standard buildings and has proven its worth. However, if architecture or use have special requirements or if innovative systems are to be used, orientation to product standards can become a corset that prevents the best and safest solution.

Better solutions would be "allowed

The Swiss fire protection regulations certainly leave a door open in this respect: VKF Guideline 27-15 "Verification procedures in fire protection" allows individual solutions even with non-certified products if it can be proven that the protection goals of the standard are met and a holistic approach is taken. However, this freedom is practically not used today by both planners and authorities - possibly because it shifts the responsibility to the parties involved. After all, how can it be proven that a special solution, which is not classified and certified as a standardized component in terms of fire protection, meets the required protection goals? In recent years, findings from materials science have flowed into civil engineering and led to the development of scientifically based experimental verification methods for the fire behavior of building components. They could enable individual solutions in fire protection that demonstrably achieve the desired level of protection.

How does a system react in case of fire?

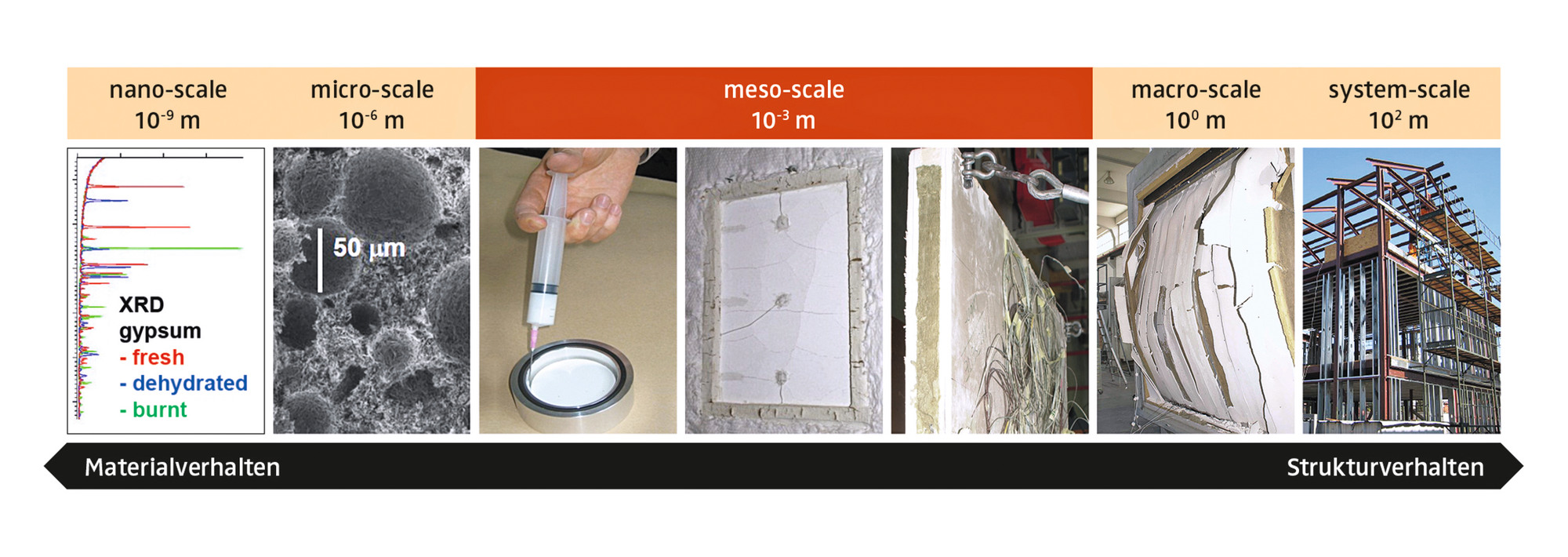

A fire in a building is an extraordinary event that puts all structural elements under multiple stresses. The high temperatures change the physical and chemical properties of the building materials at the micro level and - subsequently - the load-bearing behavior and fire compartmentation at the macro level. As system solutions are increasingly used, different subsystems and materials interact in ways that are difficult to predict. For example, how do the porous gypsum boards, the mineral insulation boards, the thin-walled steel profiles and the rigid screw connections interact in a drywall? Only when material behavior and structural behavior are considered together can reliable statements be made. Therefore, an experimental approach in different size scales, from micro to system scale, is required to be able to demonstrate the fire resistance duration of the overall system, i.e. its performance in case of fire in terms of load-bearing capacity, space closure and thermal insulation.

From micro to system scale

The meso-scale is of particular importance for experimental fire protection tests (see Fig. 1): The characteristic system components are reproduced at meso-scale and subjected to the effects of fire. In this way, the interaction of material and structural behavior can be tested without having to build the entire system on a 1:1 scale and test its fire resistance. Such verifications can reveal amazing things and allow interesting conclusions to be drawn for fire protection - as the following examples show.

Not approvable despite suitability

Glass block walls are increasingly being used in buildings as an attractive design element, even where fire protection requirements have to be met. Fire resistance tests have confirmed that glass block walls behave in the same way as typical solid walls in the event of fire. Nevertheless, openings in glass block walls cannot be closed with fire protection closures certified for solid construction walls. The reason: glass block walls are simply not addressed in European testing and product standards. However, fire tests and fire resistance tests with the glass blocks alone and in combination with the fire protection closures have clearly proven that the system sufficiently ensures thermal insulation and room closure even in the event of fire. A purely formal hurdle therefore prevents the combination of a glass block wall with a fire protection closure from being approved.

Certified products - but uncertain fire protection

The reverse case also occurs: In order to be able to offer an approvable solution, a wide variety of certified products are combined. This results in a new "system" whose behavior in the event of fire, however, is by no means known. Such "solutions" are not infrequently encountered on construction sites. In the case study (see Fig. 2), the fire protection closure was weakened by the passage of empty pipes. In terms of fire protection, it would have been very easy to solve the problem by adapting the fire protection closure locally. However, certified products were formally required for the wall, ceiling, frame widening and bulkheading. The result was an in-house design that combined the certified products on a scale that was outside the test standard - and thus entailed incalculable risks.

Goal: Performance-based fire protection

Experimental verifications mean more effort for planners and authorities than the use of certified products. At the same time, they open up great potential for individual solutions that create high aesthetic or practical added value for the building owner and the users. The (easily quantifiable) additional expense is then quickly amortized.

What the examples listed also show, however, is that even those who strictly follow the guidelines and standards are not necessarily on the "safe" side, because the standards also have "blind spots". Therefore, it is part of the expertise of fire protection professionals to know these critical aspects of certification. For example, according to the standard, framing timbers in fire protection closures can be replaced by those with a higher gross density, and without additional fire resistance testing. This is approvable in the full knowledge that the fire behavior of a timber by no means depends only on the gross density and that the fire resistance period of the fire protection closure can be shortened by replacing the timber type. Therefore, both are valid: Standards should not prevent demonstrably safe individual solutions. At the same time, however, standard solutions that conform to standards should also be critically reviewed and questioned. The goal would be fire protection that is based on the real performance of building materials and systems in the event of fire. The SIA "Fire Protection" Commission is currently working on a standard that will set the framework for this performance-based approach to fire protection. It is hoped that this will enable new solutions in both fire protection concepts and building components.

Fig. 2: The fire protection closure was weakened by the passage of empty pipes. A self-construction was created with certified products, but its effectiveness is by no means ensured at this scale.

Author

Dr. Erich Hugi

Project Manager, Basler & Hofmann