New plastic protects against flames - and waste

Empa researchers have developed an epoxy resin that can be repaired and recycled - and is also flame retardant and mechanically resistant. Possible applications range from coatings for parquet floors to composite materials for trains and aircraft.

Epoxy resins are tough and versatile plastics. In combination with glass or carbon fibers, they are used, for example, to manufacture components for aircraft, cars, trains, ships and wind turbines. Such epoxy-based fiber-reinforced plastics have excellent mechanical and thermal properties and are much lighter than metal. Their weakness: they are not recyclable - at least not yet.

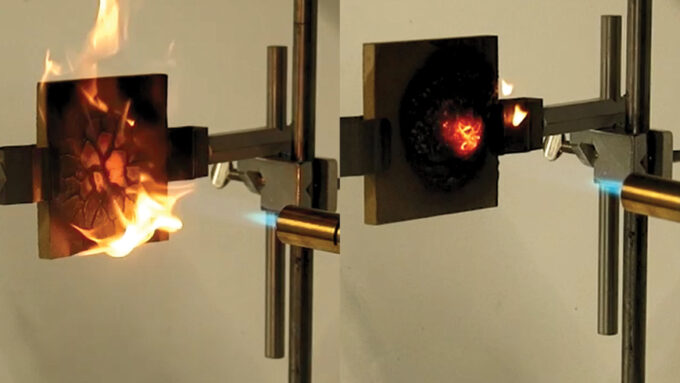

Flame retardant

Now Empa researchers led by Sabyasachi Gaan of Empa's Advanced Fibers Laboratory have developed an epoxy resin-based plastic that is fully recyclable, repairable and also flame retardant - while retaining the favorable thermomechanical properties of epoxy resins. They have published their findings in the Chemical Engineering Journal.

Recycling epoxy resins is anything but trivial, because these plastics belong to the so-called duromers. In this type of plastic, the polymer chains are closely cross-linked. These chemical bonds make melting impossible. Once the plastic has hardened, it can no longer be deformed.

The situation is different with thermoplastics, such as PET or polyolefins. Their polymer chains are close together but not bonded to each other. Under the influence of heat, these plastics can be melted and formed into new shapes. However, because of the lack of crosslinking, their mechanical properties at elevated temperatures are generally not as advantageous as those of duromers.

A new type of plastic

The special epoxy resin that Empa researchers have developed in collaboration with national and international partners is actually a duromer - but unlike other duromers, it certainly melts like a thermoplastic. The key is the addition of a special functional molecule from the phosphonic acid ester class to the resin matrix. "We originally synthesized this molecule as a flame retardant," says Empa scientist Wenyu Wu Klingler, who co-invented the technology. However, the bond that the molecule forms with the polymer chains of the epoxy resin is reversible, meaning it can be released under certain conditions. This loosens the crosslinking of the polymer chains so that they can be melted and shaped.

Such materials, also known as vitrimers, have only been known for about ten years and are considered particularly promising. "Today, fiber-reinforced plastics are virtually impossible to recycle, except under extreme conditions that damage the fibers," explains Wu Klingler. "Once they have reached the end of their useful life, they are incinerated or disposed of in landfills. With our plastic, it would be possible for the first time to put them back into the material cycle."

Their vision for the future, adds group leader Sabyasachi Gaan, is "a composite material in which the fibers and the plastic matrix can be completely separated and reused." The researcher sees a particular advantage, for example, in carbon-fiber-reinforced plastics, such as those used in the construction of airplanes, trains, boats, cars, bicycles and more. "The production of carbon fibers requires a lot of energy and releases an enormous amount of CO2," he explains. "If we could recycle them, their environmental footprint would be a lot better - and the price a lot lower." In addition, valuable additives such as phosphorus could also be recovered from the polymer matrix in this way.

Customized material

Fiber-reinforced plastics are not the only application for the new plastic. For example, it could be used to coat wooden floors, as a transparent, resistant layer that has good flame-retardant properties - and where scratches and damage can be "healed" again with a little pressure and heat.

"We didn't develop a single material for a specific purpose, but rather a toolbox," Gaan explains. "Flame retardancy, recyclability and repairability are a given. We can optimize all other properties depending on the intended use." For example, he says, flow properties are particularly important for the production of fiber-reinforced plastics, while exterior wood coatings must also be weather-resistant.

To pursue these and other applications of the material, the researchers are now looking for industrial partners. The chances of commercial success are good, because in addition to all its other advantageous properties, the modified synthetic resin is also inexpensive and easy to manufacture.

Source: Empa