High visibility clothing: safety through visibility

People who can be seen are safer. This applies not only to road traffic, but also to other working environments where people and machines work together. High-visibility clothing increases visibility even in poor lighting conditions.

In addition to protecting against mechanical, chemical or thermal risks, protective clothing can also have the function of increasing visibility. The fly agaric or red-bellied toadstool are examples of this. The colors red, orange and yellow are particularly suitable for conveying a warning effect, as they offer a high contrast between high-visibility clothing and the working environment. High-visibility clothing is part of personal protective equipment (PPE), the employer must provide it and the employees must use it.

Fluorescence + reflection

The functionality of high visibility clothing is based on fluorescent background materials, which make it easier to see in daylight. In physical terms, the applied fluorescent dyes convert parts of the UV light into a visible reflection. The eye perceives this non-directional (non-specular) reflection as a more intense glow of the colors. There are also separate reflective strips that trace the contours of the body. They increase visibility, especially at dusk, when they are illuminated by motorized vehicles.

High-visibility clothing is always used when employees

- are difficult to see, e.g. in rain, fog, snow or darkness

- work close to moving road or rail traffic, on construction sites, when directing vehicles, etc.

- are difficult to see due to the working environment (trees, vehicles, work equipment)

Standardized quality

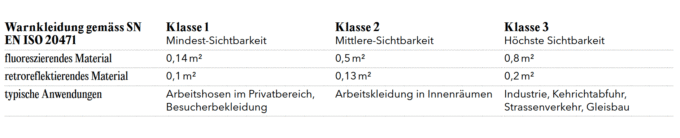

The international and Swiss standard SN EN ISO 20471:2013 regulates the requirements for high-visibility clothing and defines three protection classes. The details include requirements for tensile strength, pressure resistance and thermal resistance of the fabrics used, as well as color fastness to the effects of body perspiration.

The classification into one of the three protection classes is based on the minimum areas of the safety materials on a garment (see table)

The larger the fluorescent and retroreflective surfaces, the better the wearer of the high-visibility clothing can be recognized even at greater distances and in poor lighting conditions. Class 3 high-visibility clothing is the most widely used in industrial environments and offers the highest level of visibility. To meet the requirements of this highest level, the clothing must cover the torso and have reflective bands on the sleeves and/or trouser legs. Dungarees alone cannot therefore comply with protection class 3 as they do not cover the torso.

Correct use and care

The following applies to the use of high-visibility clothing:

- Always wear closed - whether zipper, Velcro or buttons - and do not roll up your sleeves.

- Do not wear any other clothing over it, even a sweater against the cold should always be worn under the high-visibility vest.

- Keep high-visibility clothing clean, soiling weakens the warning effect.

- Replace warning clothing if it ages, becomes weathered or damaged over time and the reflective effect diminishes.

- Store away from direct sunlight to prevent the fluorescent colors from fading prematurely.

When washing, dry-cleaning and decontaminating, you should follow the manufacturer's care instructions and, for example, observe the specified maximum number of wash cycles. The warning effect as well as, for example, the flame-retardant finish of the material can be impaired by incorrect cleaning.

If a company logo or slogan is to be applied, this may only be done in consultation with the manufacturer. This is because patches, badges or lettering can change the material properties or undermine the minimum surface area requirements. Many suppliers now offer suitable solutions for printing on high-visibility vests or high-visibility softshell jackets without compromising certification and safety requirements.

Friedhelm Kring

Freelance journalist, specialized in occupational safety

> kring.de