Machine safety - what must be observed?

The article informs the safety officer how machines should be used in the company according to the legal requirements. This can prevent changes after the purchase of the machine. This means that the machine can be used profitably in the company more quickly.

Machines must not endanger persons if they are used in accordance with the manufacturer's specifications and integrated into the working environment (Ordinance on Accident Prevention VUV, Articles 24, 32a). New machines must therefore comply with the regulations for placing on the market (Machinery Directive 2016/ 42/EC and, if applicable, other directives).

Before purchasing a machine, the operator must clarify whether the machine to be purchased is suitable for the intended use and for integration into the working environment. If necessary, the manufacturer must be informed of any desired change in the intended use. Likewise, it may be necessary to adapt the operational environment of the machine, for example because required foundations are missing or energy supplies, escape and transport routes, etc. must be adapted. Requirements of the ordinance on accident prevention, the labor law and the cantonal building laws must be observed. If the plant has to be redesigned, approval of the planned plant must be obtained from the cantonal building authorities (planning approval).

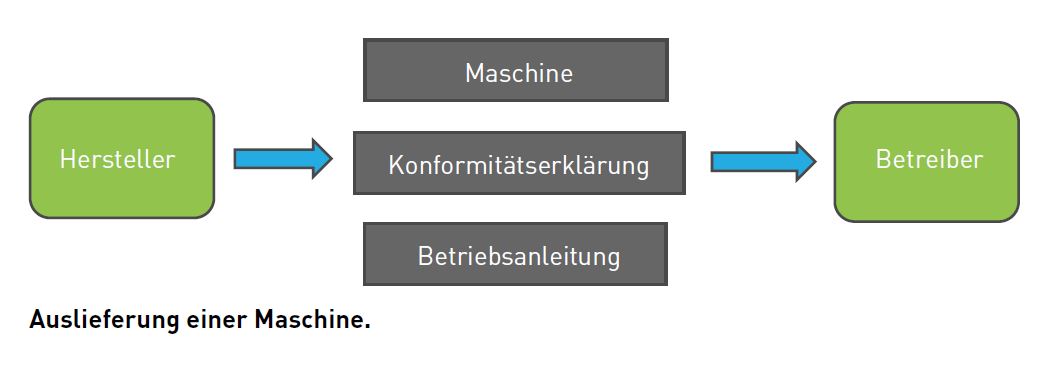

For most machines, the person placing the machine on the market - this can be the manufacturer or the importer - can alone assess whether the machine meets the requirements for being placed on the market.

The purchaser must obtain a declaration of conformity and operating instructions from the manufacturer or importer of the machine.

Declaration of Conformity

In the declaration of conformity, the manufacturer certifies to his customer the provisions that were observed during the construction of the machine. The purchaser of the machine can thus check whether the Machinery Directive and, if applicable, other relevant directives have been observed and thus whether the requirements for the use of new machines within the meaning of VUV Article 24 have been met.

Essentially, the following information must be included on the declaration of conformity:

- Name and address of the manufacturer and, if applicable, his authorized representative

- Name and address of the person compiling the technical documentation

- Description and identification of the machine

- Declaration of which directives the machine complies with

- Where applicable, the references of the harmonized standards applied

- Place and date of declaration

- Information on the person issuing the declaration

- Signature of the person issuing the declaration

If there are doubts regarding the completeness of the declaration of conformity, this document can be checked with Suva publication CE08-17.d (see under www.suva.ch/CE08-17.d).

If a purchaser of a machine imports it or manufactures it himself, he must ensure that the machine meets the requirements of the relevant regulations.

Checking the machine and the operating instructions

If it is unclear whether the machine and the operating instructions meet the legal requirements, it makes sense to first contact the manufacturer. The manufacturer is obliged by the Machinery Directive to carry out a risk assessment and risk reduction during the development phase of the machine. He should therefore be able to justify the choice or non-choice of protective measures.

The law does not require the manufacturer to disclose the risk assessment/mitigation documentation to its customer. Therefore, the manufacturer may refuse to allow the customer to inspect the mentioned documentation.

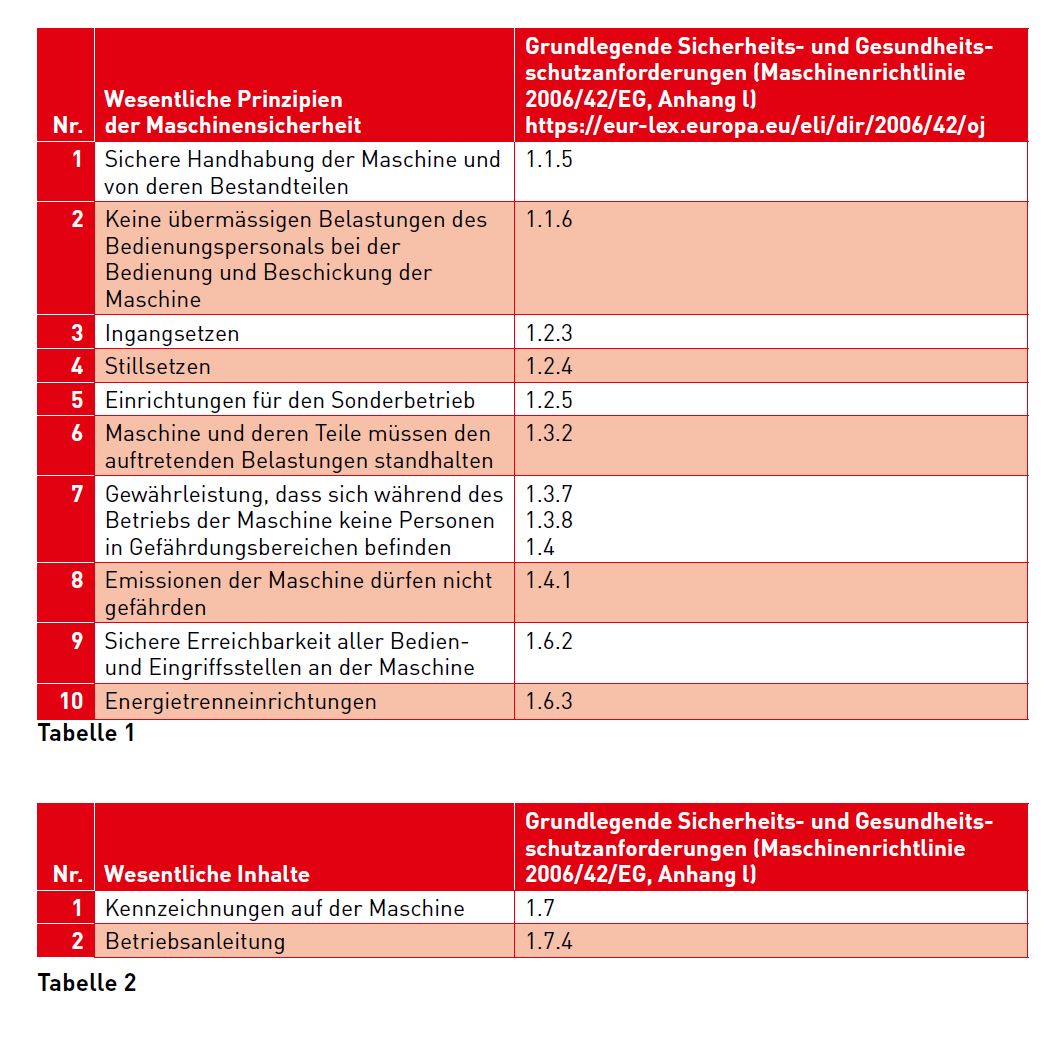

In the following, we will show how the operator can check the purchased machine and the operating instructions for obvious defects by using the basic safety and health requirements (Machinery Directive 2006/42/EC, Annex l) to check whether the most important principles of machine safety have been implemented and the most important information about the machine is conveyed to the user (see Table 1 and 2).

Example: Milling machine for metalworking (1st part)

The operating instructions for a computer-controlled milling machine require the removal of a fixed guard without further protective measures in order to observe a setting on the switched-on machine.

Under the principle No. 5 in Table 1, "Devices in special operation", reference is made to the basic requirement 1.2.5. Under this item, among others, the following conditions are mentioned for the operation of the machine with the guards removed:

- Operating mode selector switch, which can be locked in any position, for selecting the appropriate operating mode and preventing non-selected operating modes;

- the operation of hazardous functions must only be possible as long as the corresponding command devices are actuated, and hazards from command chaining must be eliminated;

- the operation of hazardous functions must only be possible under low risk conditions;

- dangerous functions, triggered by action on sensors, must not be possible.

It can thus be established that the procedure described in the operating instructions does not comply with the essential health and safety requirements of the Machinery Directive.

In-depth review of machine and operating instructions

If the procedure described above has not yet provided sufficient clarification of the safety of the machine, the machine can be examined in greater detail with the aid of standards, which specify the fundamental health and safety requirements of the Machinery Directive. In the area of standards which concretize the Machinery Directive, a distinction must be made between the following types of standards:

- Type A standards (basic safety standards) deal with basic concepts, design principles and general aspects that can be applied to machines

- Type B standards (basic safety standards) deal with a safety aspect or a type of protective device that can be used for a whole range of machines

- Type C standards (machine safety standards) deal with detailed safety requirements for a specific machine or group of machines

In order to demonstrate the conformity of the machine with the requirements of the Machinery Directive, the manufacturer may mention the standards observed during the construction of the machine in the Declaration of Conformity.

The European Official Journal lists standards which, if observed, may be presumed to satisfy the essential requirements of the Machinery Directive (https://ec.europa.eu/growth/single-market/european-standards/harmonised-standards/machinery_en).

If standards have been mentioned by the manufacturer in the declaration of conformity, these can be checked with the help of the EU Official Journal.

For a detailed check of the machine, first obtain the Type C standard relevant to the machine. The protective measures with which the risks of the machine can be sufficiently reduced are mentioned there. If detailed information on an individual protective measure is required, the relevant type B standard can be used to clarify whether the protective measure available on the machine is sufficient. In the Suva publication CE19-1.d (www.suva.ch/CE19-1.d), frequently used type B standards and publications are mentioned in which safety aspects and protective devices are described in detail.

Standards can be obtained from the Swiss Association for Standardization (www.snv.ch) can be obtained.

The law stipulates a two-year warranty. If defects are reported to the manufacturer within the warranty period, he must remedy them free of charge. The same applies to defects in the operating instructions.

Example: Milling machine for metalworking (2nd part)

As already mentioned in the first part of the application example, when operating a machine with the guards removed, substitute measures are required in the essential health and safety requirements. The relevant Type C standard for milling machines in metalworking EN 13128:2001+A2:2009 describes, among other things, the following measures for operation with the guards removed:

- Axis movements limited to 2 m/min., triggered by command device with automatic reset (inching switch)

- Spindle rotation initiated and maintained with the following devices:

- Command transmitter with automatic reset (inching switch)

- Spindle start command device in connection with an enabling device

The spindle speed must be limited so that the spindle can be stopped within two spindle revolutions (idle).

If a Type C standard exists, the state of the art for a machine can be determined relatively easily.

Operating machines

The operating instructions provide the operator of the machine with information on the intended use and safe handling of the machine. The operator must use the machine as intended and observe the information in the operating instructions (VUV, Art. 32a). This means that the company must instruct those persons who work with the machine or could come into contact with it in accordance with the operating instructions (VUV, Art. 6).

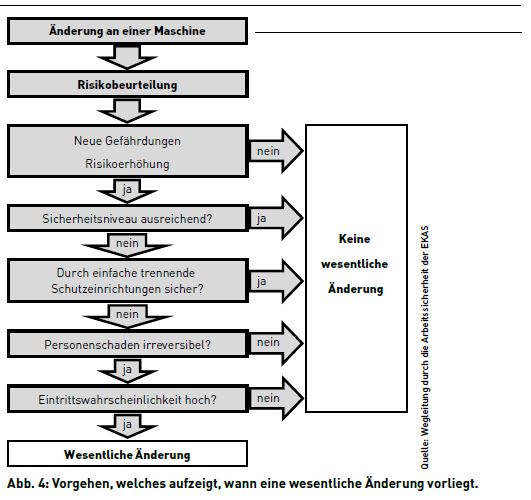

Change machines

If a machine is substantially modified or used for a purpose other than that for which it was intended, the newly arising risks must be mitigated in order to ensure the safety and health of persons (VUV, Art. 32a). This requires that an assessment of the risks must be made each time the machine is modified. If new risks arise due to a change in the intended use, performance or function, this may be a significant change.

If it is determined that the existing protective measures on the machine are no longer sufficient, these must be supplemented. Depending on the new protective measures required and the magnitude of the risk, the provisions for new machines must also be observed when modifying old machines (see Fig. 4 below).

If only the function and performance of the machine are to be maintained and adaptations are necessary because the original spare parts can no longer be procured, this does not normally constitute a significant change. The risks resulting from the adaptations must be assessed and, if necessary, mitigated.

For machines that were placed on the market before 1997, the requirements of the Ordinance on Accident Prevention Art. 25 to 32 and 34 paragraph 2 must be observed. A possible concretization of these requirements is shown, among others, in the EKAS guideline no. 6512 "Work equipment".

For machines that were placed on the market for the first time after 1996, the provisions for placing on the market that were valid at the time of placing on the market must be observed.

Mauritius Bollier, Masch. Ing. HTL, Safety Engineer, Suva, Technical Division